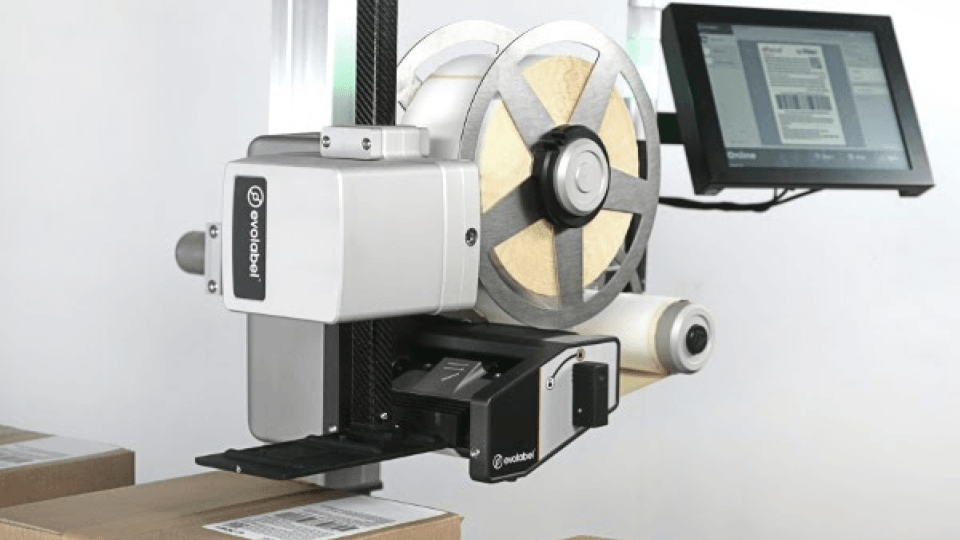

Label Applicator Line is used for labeling mail pieces semi-automatically for more efficient further processing. The Label Applicator Line consists of a conveyor belt, an OCR camera equipment, and a label applicator.

The device is able to recognize and utilize an existing barcode on the mailpiece. If no barcode is found, a new one will be printed.

Mailpiece data is stored on the Mailroom Manager server and images of unrecognized mailpieces can be directed to remote coding service.

Benefits

- Cost-efficient processing

- Enables code based sortation

- Enables efficient remote video coding

Used for sorting and registration

- Rest mail

- Small and medium-size parcels

Locations

- Sorting centers

- Terminals

| Max. speed | 3000 – 6000 pcs /hour |

| Shipment max dimension | 400 x 400 x 300 mm |

| Emergency button | Yes |

| Lights indicating the operation (RUN, START, STOP) | Yes |

| Power supply | 400VAC, 50Hz, 16A |

| Compressed air supply | Required pressure at least 6 bar |

| Dimensions | (L)10 m x (W) 5 m x (H) 2.5 m |

| OCR Line Camera | Resolution: 8160 Pix

Sensor: highly sensitive monochrome CMOS TDI with 192 (128 + 64) rows Line rate: 300 kHz (monochrome) Pixel size: 5 µm x 5 µm |

| Label Applicator | Direct thermal

Label size (WxL) 30×20 to 118×240 mm Resolution 300dpi Max print speed 200 mm/s Symbologies: CODE128, GS1-128, GS1-Databar, Interleaved 2 of 5, Pharmacode, UPCA / Datamatrix, PDF-417, QR code |